Heavy-duty equipment chiptuning

Why perform chiptuning on heavy-duty machinery?

Machine owners are often struggling with the fact that the purchased machines do not provide enough power to handle difficult working conditions or heavy loads. However, purchasing more powerful machines is a very expensive solution. Another problem is the high fuel consumption of the machines, which means high costs for the company, especially if the machines are working for long periods and with heavy loads. Chiptuning is an effective and affordable way to improve the performance and efficiency of your heavy-duty machinery fleet and reduce company costs.

We specialize in heavy-duty machinery chiptuning. Our experienced team has increased the power of over 250 different machines and solved over 300 exhaust-gas aftertreatment problems. We have tuned heavy-duty machinery throughout Scandinavia, the Baltics, and Central Europe. Whether your fleet consists of tractors, combine harvesters, harvesters, forwarders, excavators, loaders, trucks, or any other heavy-duty machinery, we are always here to help!

Generally, we come to you and perform the work on-site!

Higher Torque and Power

Through chiptuning, engine power and torque typically increase by up to 20%, allowing tractors, excavators, harvesters, or trucks to perform heavy work significantly more efficiently – faster and with less effort.

Many heavy-duty machinery manufacturers offer the same model in different power classes, with engines that are technically identical. The difference lies in the engine control unit (ECU) software, which limits or adjusts the engine's power according to marketing or usage needs.

For such machines, it is possible to significantly increase the power by optimizing the engine control unit software – up to 50% compared to the factory settings.

Lower fuel consumption

Thanks to the increased torque and power, the machine performs the same work at a lower engine speed or even in a higher gear, which reduces the machine's fuel consumption by up to 20%.

The reduction in fuel consumption means significant savings in daily use and makes the machines much more cost-effective in the long run.

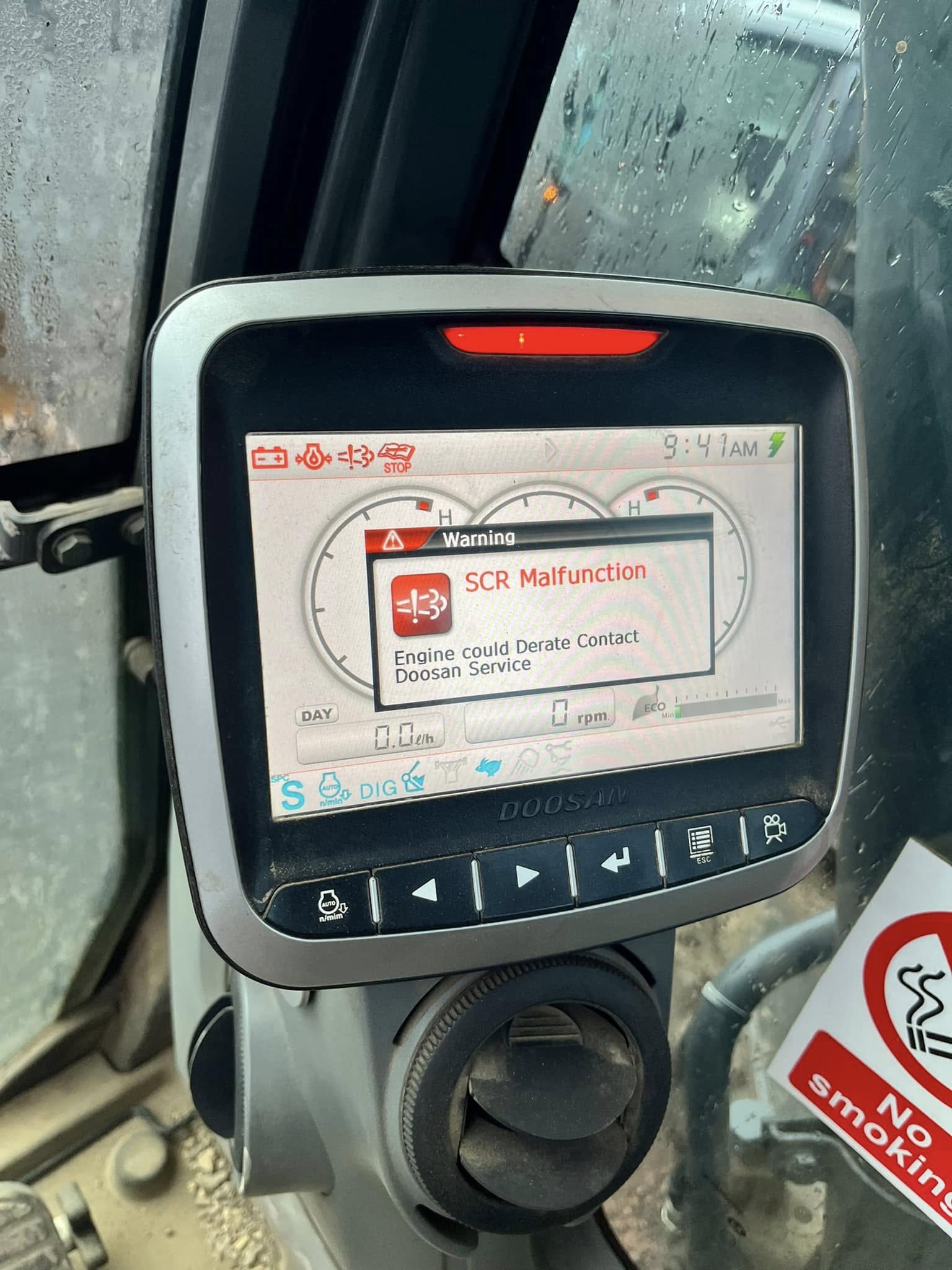

Downtime due to exhaust-gas aftertreatment

Downtime of heavy-duty machinery related to failures in exhaust-gas aftertreatment systems is one of the most common and costly issues faced by companies.

We offer a quick and cost-effective software solution that allows for the removal of exhaust aftertreatment systems from the engine control unit. This means that systems such as DPF, EGR, and AdBlue/SCR are disabled via software.

- The failing system no longer needs to be repaired.

- You will never face a situation where work is halted due to a failure in the AdBlue, DPF, or EGR system.